Applications

Primary breakdown

3D scanning for carriage headrigs

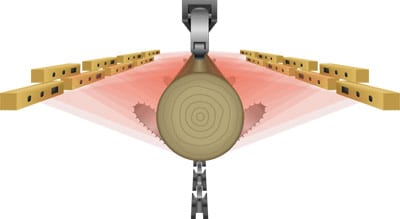

The carriage headrig has continued to evolve with the industry – from manually operated to photo-cell arrays to front-side-only shape scanning. And today, complete-coverage 3-D scanning is the gold standard. The latest complete-coverage 3-D scanning is based on our next-gen JS-50 scanners, known for their simplicity, flexibility and reliability.

3D scanning for carriage headrigs

By scanning both the front and back side of every log, our scanners provide the optimizer with a complete picture of the possible value of every log. The optimizer can then select a cut that maximizes that value.

Flexible placement

Feedback from optimization engineers inspired a new, flexible-placement design for our X6B model scanners. This new design allows for convenient end-to-end installation of our carriage scanners, while still maintaining 6 inches between lasers. The final result is a simpler scanning system capable of scanning any length log in just 6 inches of travel.

3D scanning for sharp chain infeed

Many mills are finding that a short infeed JoeScan optimized sharp chain offers one of the best values around. You can get full auto-rotation and skew, with the low cost, easy maintenance and reliability of a sharp chain infeed. Previously, these benefits required million-dollar upgrades to huge and complex double-length infeed systems.

Output that matches your optimizer

One of the biggest problems in any optimized system is ensuring the piece doesn’t move after it has been scanned. With a well-designed sharp chain infeed, you get a full 3-D scan of the log after it is fully impaled on the sharp chain, leaving minimal opportunity for the log to shift before hitting the saws. Customers with JoeScan scanning systems are continually amazed at how precisely the boards and cants coming out of their sharp chain match what the optimizer was attempting to produce.

Is your scanning system effective?

One of the biggest problems in any optimized system is ensuring the piece doesn’t move after it has been scanned. With a well-designed sharp chain infeed, you get a full 3-D scan of the log after it is fully impaled on the sharp chain, leaving minimal opportunity for the log to shift before hitting the saws. Customers with JoeScan scanning systems are continually amazed at how precisely the boards and cants coming out of their sharp chain match what the optimizer was attempting to produce.

Secondary breakdown

3D scanning for lineal edger infeeds

Lineal-edger scanning in a tight space

You want to go lineal. You want the low maintenance and high accuracy that only lineal scanning can give, but you just don’t think you have enough space. Well, it’s time to reconsider. JoeScan makes lineal scanning possible, even for short-coupled infeeds.

How does it work

By having multiple scan zones, with each zone responsible for scanning just a portion of the board, you can get a full lineal scan with as little as six inches of travel. We know, because we’ve installed systems that do precisely that. Our scanners offer the flexibility to match the number of scan zones to your space and budget requirement.